The seminar programme at SIAF Guangzhou is the most important platform for information sharing and networking for industrial automation and its applications in China. In the seminars, you can:

- Access to the current and future developments in industrial automation

- Understand common problems and their solutions

- Discuss and exchange experiences with invited delegates

The 2019 programme was from 10 – 12 March 2019.

SIAF Conference 2020 Schedule at a Glance

*Amendment to the above schedule is possible, please refer to the final agenda on-site.

| Conference Room 1 |

|

||

| AM |

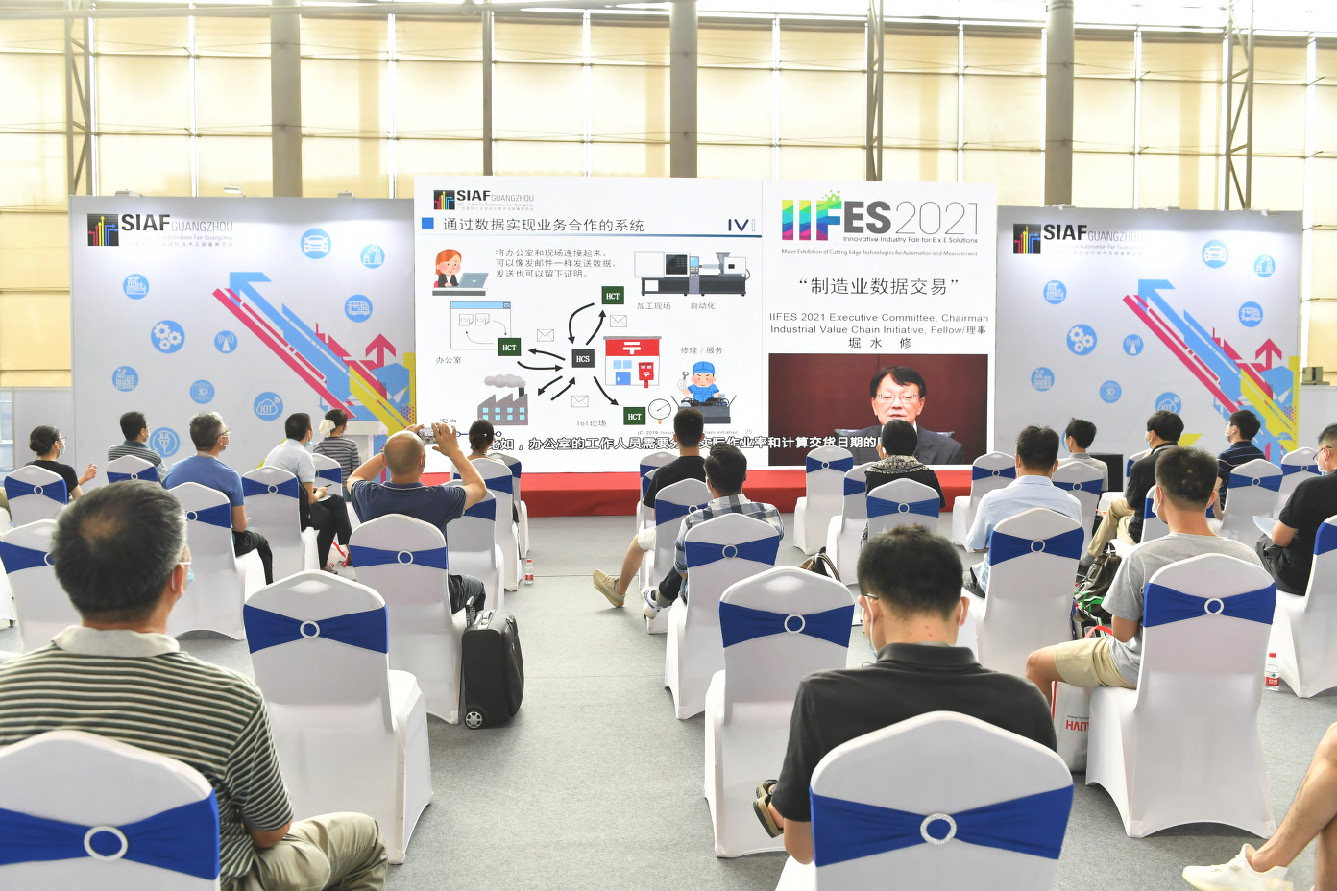

Opening Ceremony CPS (Cyber Physical System) and data transactions in Manufacturing -IIndustrialValue Chain Initiative (IVI) |

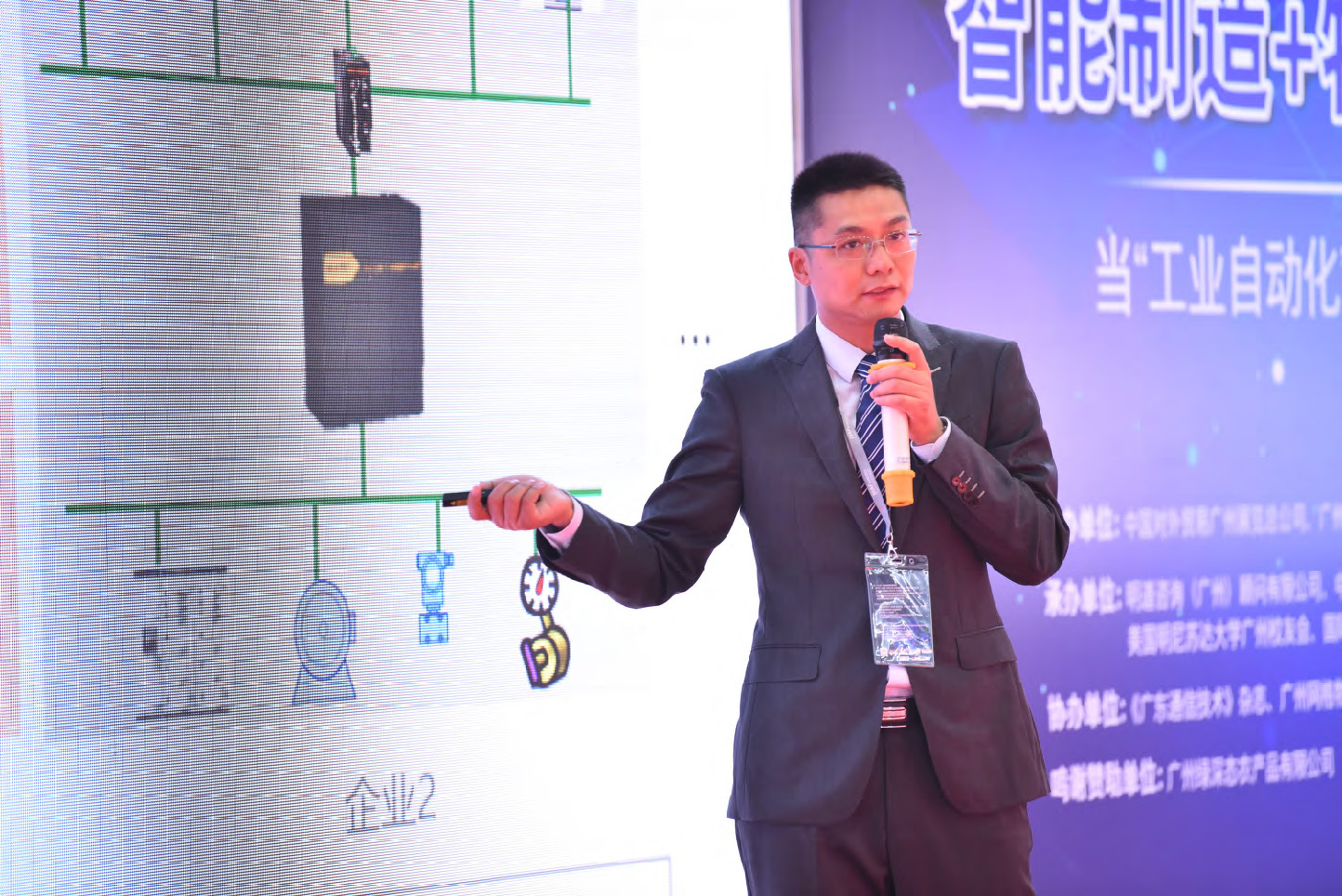

"Smart Manufacturing in 5G Era" ForumInnovation-Driven, Digital Upgrade -5G New Infrastructure + Smart Manufacturing -Gongkong |

Smart Industry Solutions-Robotics/drives |

| PM |

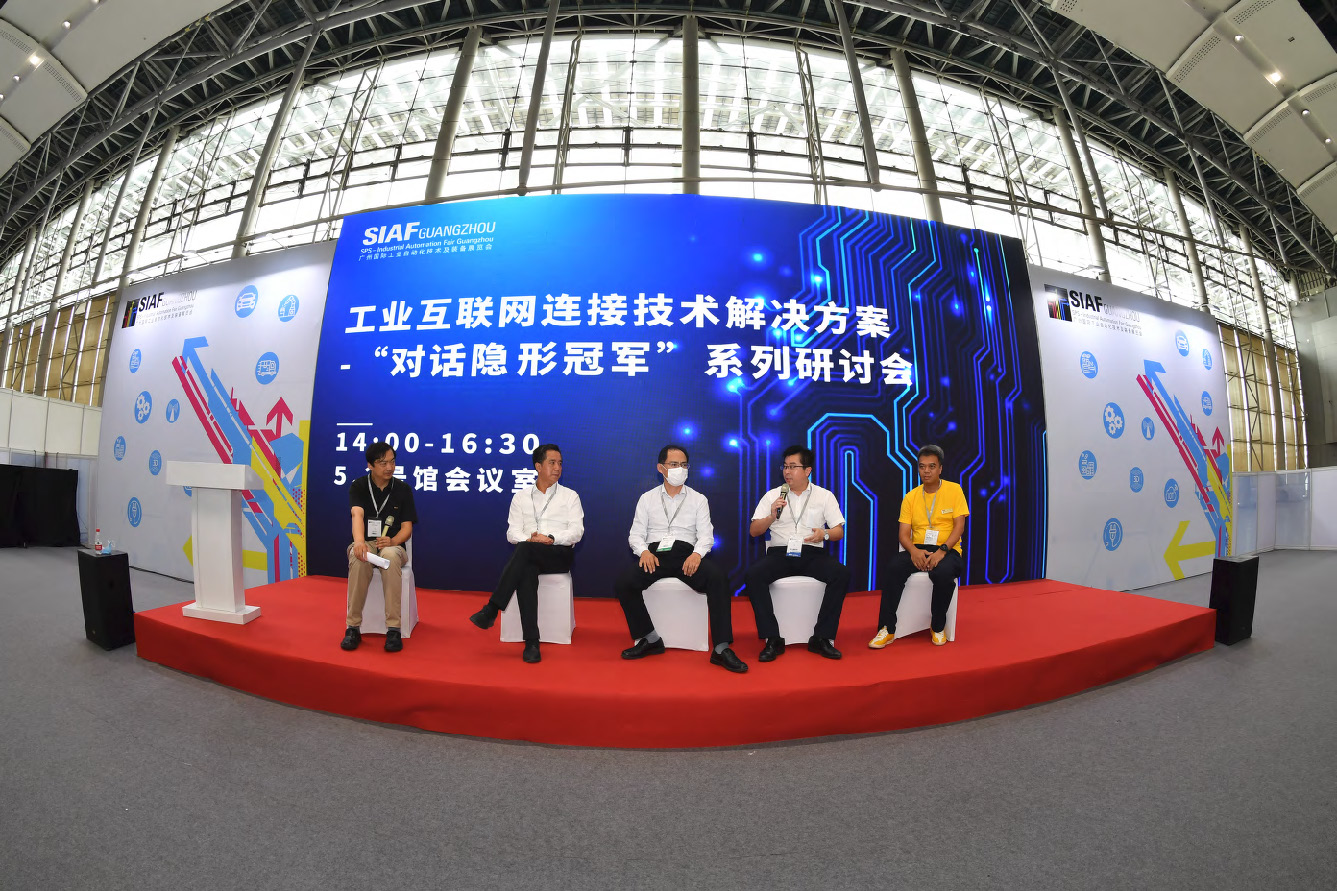

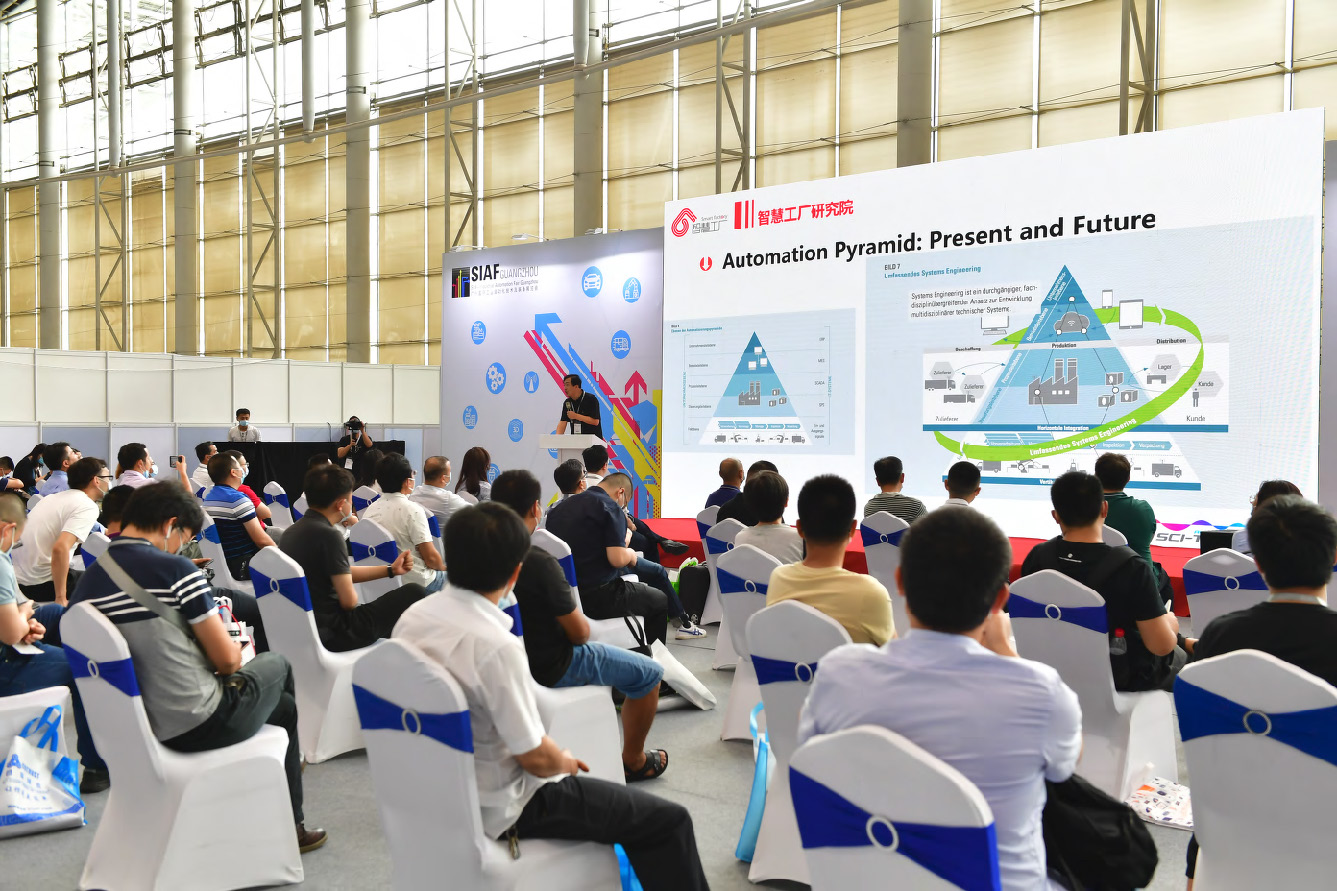

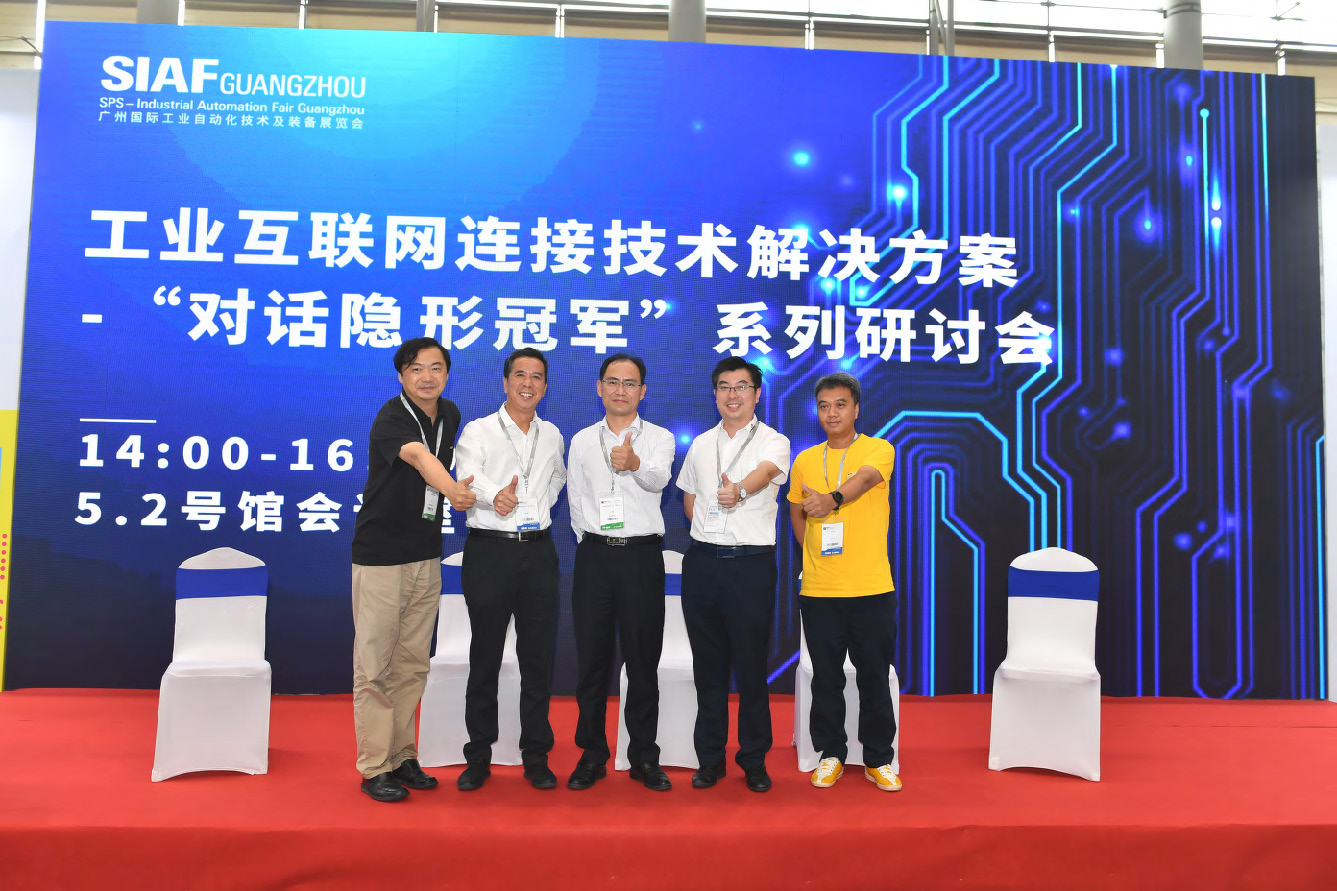

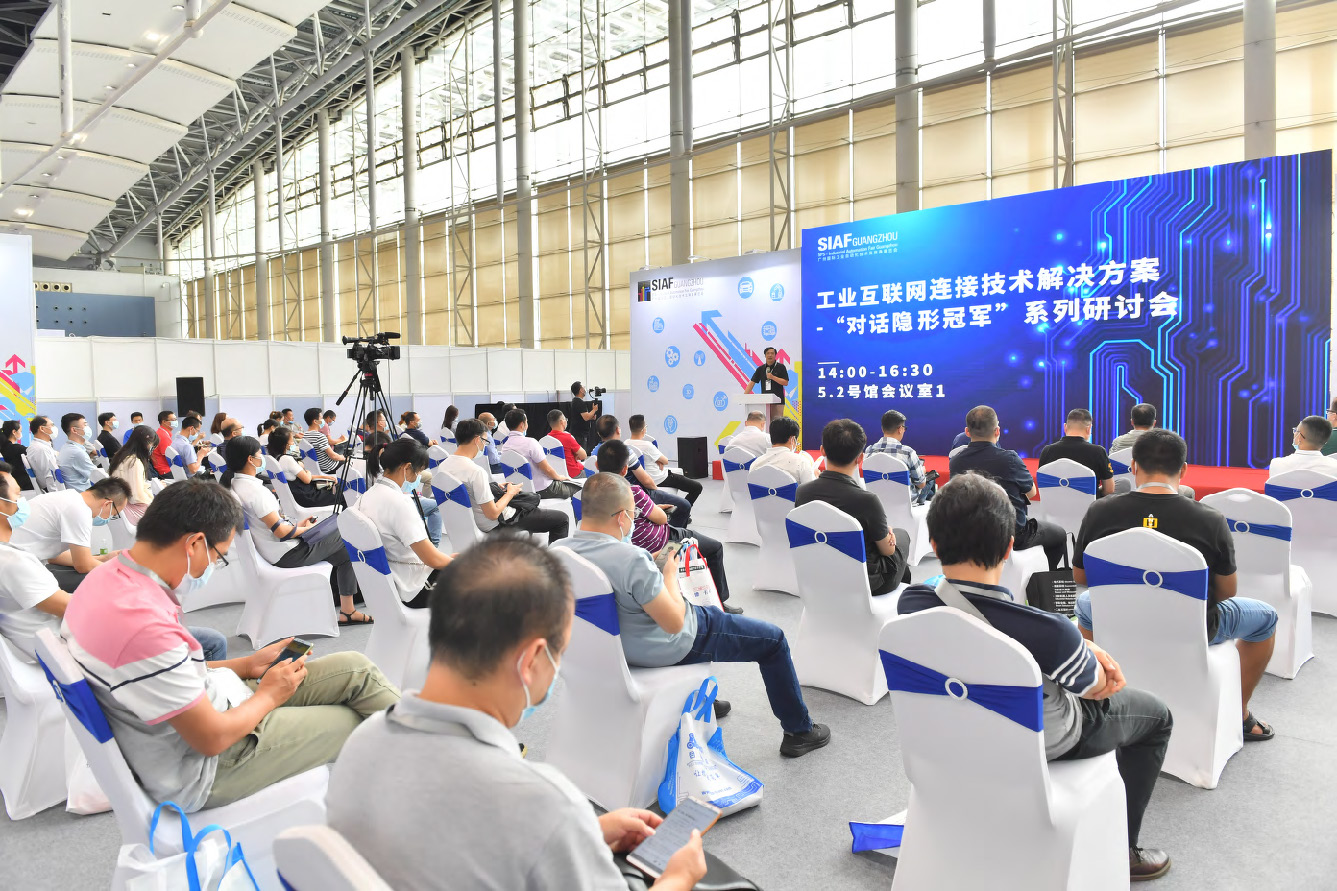

Industrial Internet Connecting Solutions -“Hidden Champion” Series |

IT meets Automation -OPC Foundation |

|

| Conference Room 2 |

|||

| AM |

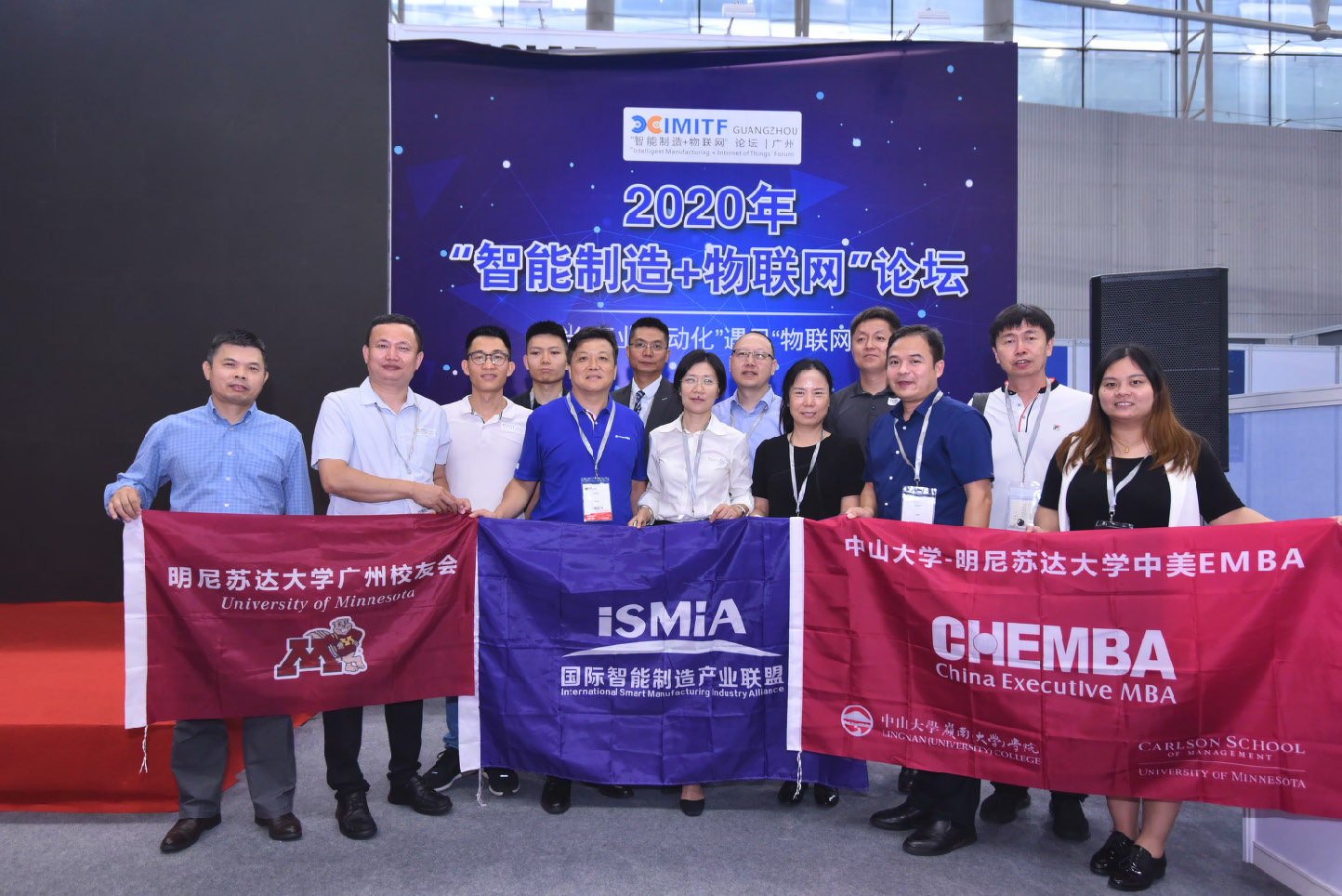

“Smart manufacturing + IoT” Seminar International Smart Manufacturing Industry Alliance (iSMiA) Specialty Committee of Internet of Things

|

Smart Industry Solutions-Sensor 4.0 |

Smart Industry Solutions-Preventive/Predictive Maintenance |

| PM |

Applications of Digital Factories in Manufacturing under New Infrastructure -ilinki.net |

||

| Conference Room 3 |

|||

| AM |

TSN/A Forum -Weka& AVNU |

TSN/A Forum -Weka& AVNU |

|

| PM |

TSN/A Forum -Weka& AVNU |

TSN/A Forum -Weka& AVNU |

|

| Cleanzone Talk |

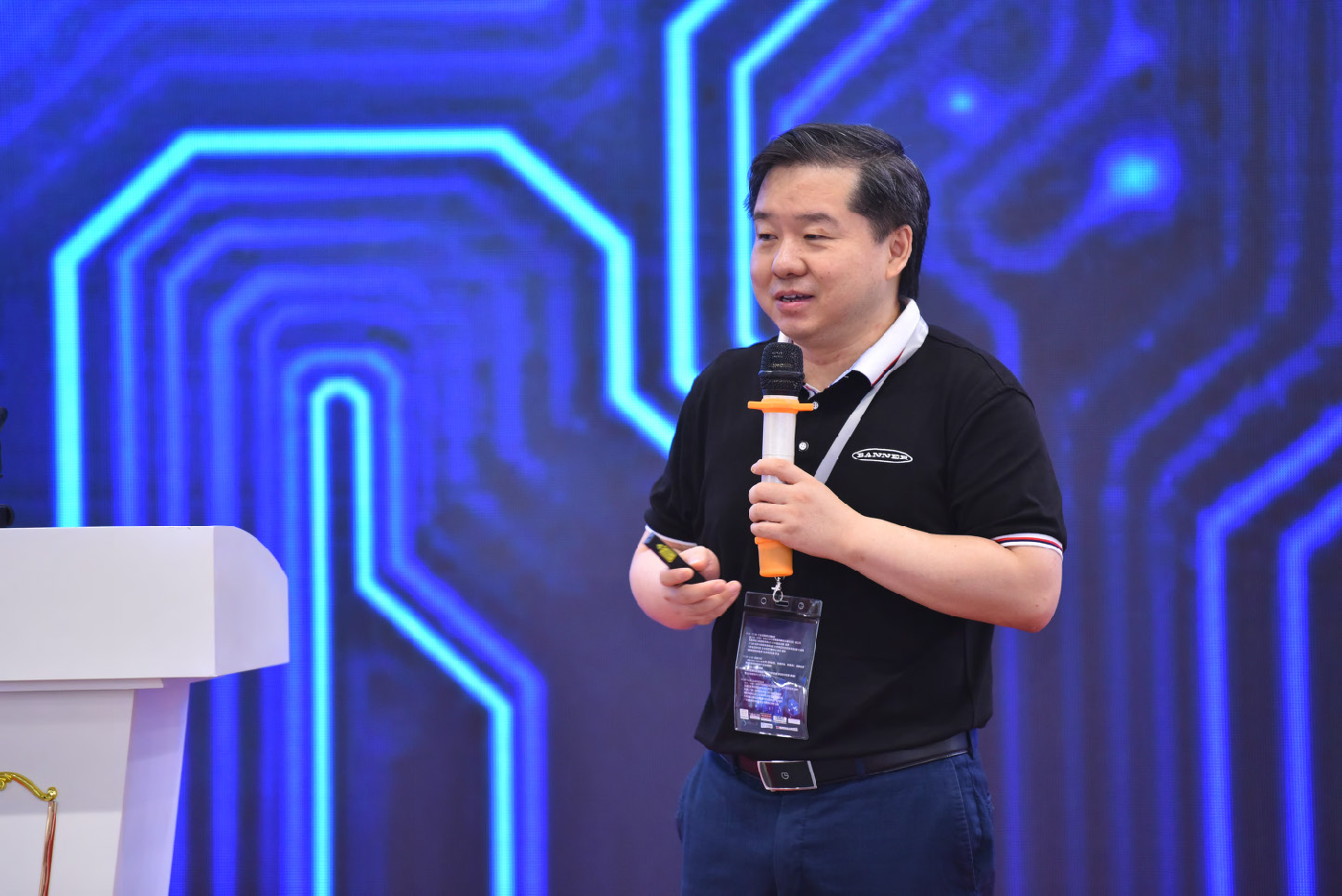

SIAF Guangzhou 2020 Conference impression